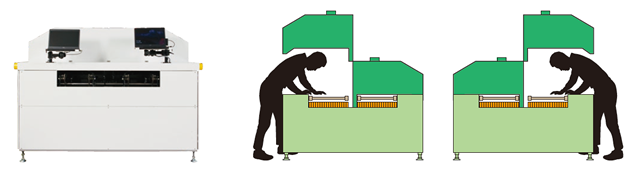

Independent double chambers materialize non-stop operation

- Enables non-stop operation

- Allows free execution of temperature profiling

- Improvement of maintainability

- Saves 50% space

Enables non-stop operation

Two independently opening and closing top lids allow maintenance to be performed without stopping the operation

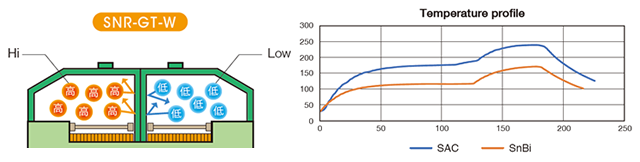

Allows free execution of temperature profiling

Independent chambers stop heat interference between the adjacent chambers

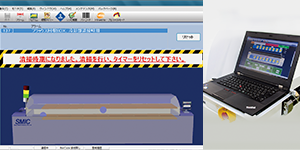

Laptop display panel

Easy operability by 3D display

Intelligent stand-by mode

Time reduction mode that achieves substantial energy saving

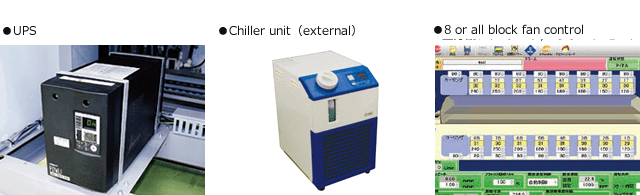

Other equipment

- PLC+PC control

- Heating zone flux management system

- PCB fall detection

- PCB counter

- ECO-mode function (divided into 8 blocks)

- Oxygen analyzer

- Automatic oxygen concentration control

- Intelligent stand-by mode

- Profile measurement mode

- Independent fan control (tripartition)

- Conveyor special surface treatment(chain, key materials and sprockets)

KIC system collaboration

SMIC's unique mechanism to reduce the thermal profile collection time

Automatic changeover by bar code

A function that enables easy setup changes without errors

Other optional equipment

- Up/down mechanism of top-bottom labyrinth curtains

- Automatic conveyor width adjustment (conveyor rail)

- Automatic conveyor width adjustment (warp prevention)

| SNR-830GT-W | SNR-1033GT-W | ||

|---|---|---|---|

| Dimensions (L×W×H) | 6,000 x 1,930 x 1,480 mm | 6,900 x 1,930 x 1,454 mm | |

| Conveyor height | 900±20 mm | 900±20 mm | |

| Conveyor speed | 0.3 - 2.0 m/min | 0.3 - 2.0 m/min | |

| PCB dimensions | W: 50 - 300 , L: 100 - 400 , T: 0.8 - 3.0 mm x 2 lanes | W: 50 - 330 , L: 100 - 400 , T: 0.8 - 3.0 mm x 2 lanes | |

| Component height | ≦10mm [OP: 30mm], ≧5mm [OP: 25mm] | ≦10mm [OP: 30mm], ≧5mm [OP: 25mm] | |

| Heated zones | 8 | 10 | |

| Cooling zones | 1 | 1 | |

| Side edge clearance | 3 or 4 or 5 mm | 3 or 4 or 5 mm | |

| N2 (Nitrogen) gas supply | [≧99.999%, ≧0.4MPaG, max. 600NL/min] x 2 | [≧99.999%, ≧0.4MPaG, max. 600NL/min] x 2 | |

| N2 (Nitrogen) gas usage | Component height/STD:≦100mm, ≧5mm | [250NL/min] x 2 | [250NL/min] x 2 |

| Power requirement | [200V, max. 30kW, 90A, 3-phase] x 2 | [200V, max. 48kW, 140A, 3-phase] x 2 | |