Recently, the world situation and social environments have been facing enormous changes posed by many factors including intensifying geopolitical tensions and economic instability, rapid advancement of next-generation technologies represented by generative AI, digital transformation, and automated driving and operation, as well as climate change-induced abnormal weather and large-scale disasters. Given these conditions, it is difficult to predict the future of business and society, and many businesses are facing significant changes with regard to customer demands and expectations.

The SMIC Group is striving for growth together with customers and society, principally by accurately grasping the true nature of their needs and offering value to accommodate such needs. Toward this end, we are accelerating efforts to develop new products that can support new technologies to be adopted by many customers for carrying out sustainability activities, while improving research and development as well as production capabilities at overseas sites. To ensure that these efforts will achieve successful results, we believe that it is essential to pursue continuous evolution by continuing to take up new challenges related to technology and innovation.

SMIC Group’s business activities contributing to sustainability

In accordance with its commitment to contribute to sustainability primarily by realizing a sustainable society through its business activities, and as a manufacturer that uses natural resources as raw materials, the SMIC Group thinks in earnest about what it should leave for future generations. In this context, we are promoting environmentally friendly business activities while taking on global challenges to achieve carbon neutrality and circular economies.

As part of our efforts to achieve carbon neutrality, we have launched an energy generation project to produce electricity by utilizing an ammonia-based hydrogen generator, a long-standing technology we have used in the manufacture of sintered materials. In addition to hydrogen, we are considering similar demonstration projects to implement non-fossil fuel clean energy-based non-utility power generation, while exploring the possibility of expanding the scope of target sources and ensuring our continued efforts. Also, we will continue to provide the low-temperature soldering solution series MILATERA, a technology developed to implement tin-bismuth (Sn-Bi) alloy low-temperature solder mounting in a bid to help reduce CO2 emissions.

In the circular economy area, we are taking action by ramping up ongoing solder recycling activities by increasing the use of reused and recycled materials purchased from outside the SMIC Group in addition to those sourced from internal recycling systems, with the aim of building manufacturing systems that can run lines with less input of virgin resources.

SMIC Group’s initiatives for responsible minerals sourcing

The responsible minerals sourcing policy is about avoiding the use of minerals that pose risks associated with CSR issues centering on human rights infringement. Relevant initiatives have been growing internationally, expanding the scope of regulated minerals from the initial four metals―tin, tantalum, tungsten, and gold, collectively called “3TG”―as well as risk categories to be covered, giving rise to increasingly intense demand for industries to choose safe and risk-free raw materials.

When the situation that is known today as “conflict minerals” emerged as an issue mainly in Europe and the U.S., I was posted in the US office. While working in the country, I read and viewed firsthand media reports on inhumane situations taking place in Democratic Republic of the Congo and surrounding countries where conflict minerals were a cause of severe human rights abuses and a source of funding for armed groups. This evoked in me a strong feeling of resentment, and I promptly requested the company to take appropriate actions. As a result, SMIC joined the Responsible Business Alliance (RBA) in 2011 immediately after Section 1502 of the Dodd-Frank Act was passed, along with the Responsible Minerals Initiative (RMI) in 2014. Since then, we have been making sincere efforts to ensure responsible minerals sourcing in accordance with the RBA’s guidelines.

As a manufacturer that uses tin, a conflict mineral, as a primary raw material, we are taking several specific steps. While conducting measures in reference to the relevant due diligence guidance published by the OECD, we are working to raise the recycling rate of tin and solder and increase domestic procurement, looking to reduce the risk associated with conflict minerals.

Securing human resources for the future and building appropriate systems

Addressing issues related to human resources, such as countermeasures against the shrinking working-age population resulting from the declining birthrate and aging population, as well as personnel development, is one of our overriding management themes. Although SMIC is an unlisted company, we have been striving to improve working conditions and establish appropriate employment systems with reference to the recommendations of major economic associations. This reflects our belief that it is management’s essential responsibility to develop stable employment systems for employees to work with peace of mind.

We have begun to discuss the development of personnel systems, centering on building frameworks to enable young employees to gain extensive experience from early on, with the objective of not only increasing the possibility of employees seizing career-building opportunities but also enhancing understanding of individual employees’ aptitude both by management and the employees themselves.

At the same time, we recognize that in order to deal with areas suffering from personnel shortages, it is imperative to develop proactive recruiting activities targeting specialists with adequate knowledge and experience to fill the gaps. Additionally, the company needs to prepare a solid basis to support each individual employee to fulfill their potential and grow professionally. To this end, we are also endeavoring to maintain and enhance governance systems.

Aiming for global distribution of our high-quality sprinkler products

In 2024, Senju Sprinkler Co., Ltd., an SMIC Group company, celebrated the 50th anniversary of its founding. Since 1963, when the fire sprinkler head we developed became the first to acquire type approval as a Japan-made product in its category, we have been consistently providing high-quality sprinkler products by exercising our excellent technical capabilities and continuing to be a domestic market leader. In 1995, we advanced into the North American market, but suffered from slow sales growth in the earliest days. Subsequently, however, our products began to gain a high reputation for their strong reliability and superior design quality, giving traction to demand growth. As a result, we have started a construction project to build a new factory in the U.S.

Senju Sprinkler experienced a significant upturn after taking the audacious step of responding to the issue related to perfluoroalkyl and polyfluoroalkyl substances (PFAS), a source of recent concern. Accommodating the pressing need to meet the requirements for fire extinguishing foam concentrates, which are commonly located in factories and large parking facilities, to be free from specified types of toxic PFAS, posed an enormous challenge for the company, which had specialized exclusively in sprinkler devices such as sprinkler heads. However, it undertook a joint project with SMIC to develop PFAS-free fire extinguishing foam concentrate, resulting in the release of the product in 2025. We are proud of this achievement in light of the social significance of providing fire extinguishing capabilities to prevent large-scale fires while avoiding having harmful impacts on the surrounding environment.

At present, the installation rate of sprinklers in residential and smaller-scale facilities is relatively low in Japan, slightly lower than other countries such as the U.S. Moving forward, we will work more proactively to expand the sprinkler market while heightening public awareness about preventing fire disasters.

The SMIC Group will engage earnestly in business activities to meet your needs while contributing to the realization of a sustainable society. We look forward to your continued support and encouragement.

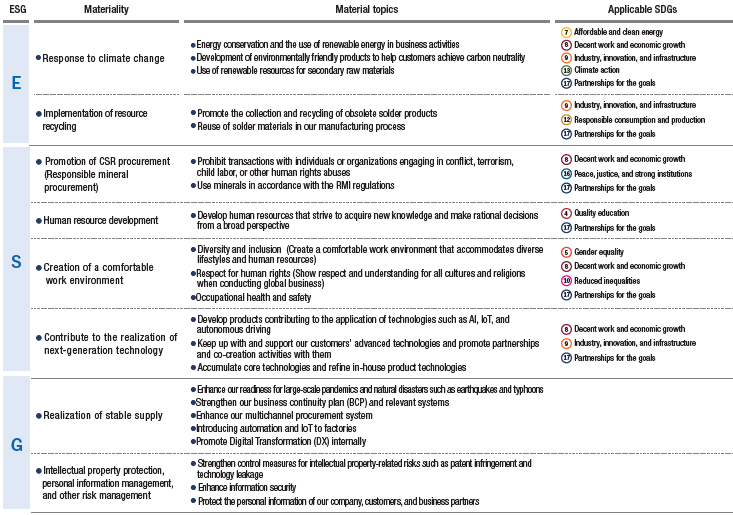

Our Materiality