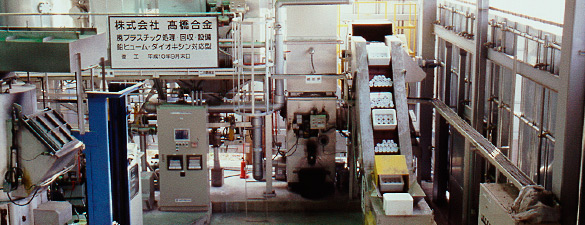

Solder Recycle System

A "resource-recycling society" aimed at protecting the global environment and effectively utilizing resources is already in the works with the establishment of related laws and regulations.

A "resource-recycling society" aimed at protecting the global environment and effectively utilizing resources is already in the works with the establishment of related laws and regulations.

As a leader in the field, our company, has developed and is running a solder recycling system along with one of our associated companies "TAK-G" since 1997, in order to promote zero emission and material recycling, and to put resource recycling into practice for our electrical and electronic device manufacturer clients.

This recycling system uses a special technology that restrains the generation of toxic substances to the minimum and an independent refining method to regenerate solder with a high level of purity, so our customers can feel secure using it.

History

1996 - Establishment of a recycle treatment plant

1999 - Improvements based on dioxin regulations and amplification of processing capacity to increase receipts

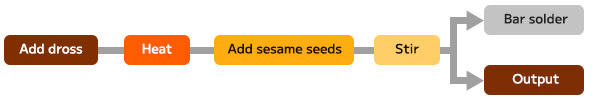

Lead-free Solder Compatible Recycling Device "SDS2-5N"

This machine efficiently separates solder and oxides from solder dross, which is becoming more common in lead-free solder.

Specially processed sesame seeds (E-sesame) are mixed with solder and dross, and the machine separates the solder and oxides by stirring them over heat. The solder is then poured into a simple mold and reused as solder bars.

About 90% of solder can be recovered.

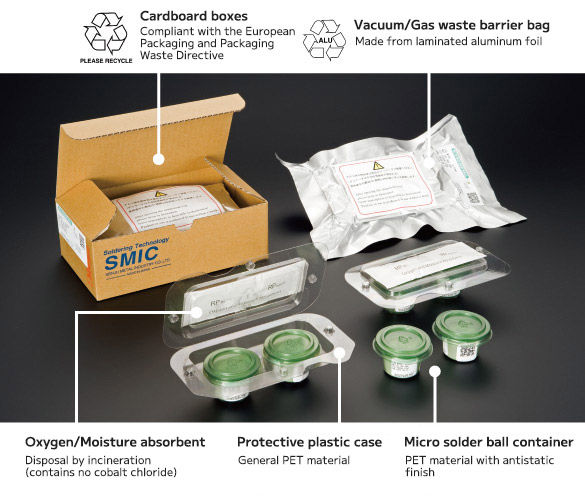

New Packaging for Micro Solder Balls

Traditionally, minutely processed solder balls required plastic, which cannot be disposed of, except in a special recycling facility. Recently, SMIC has introduced a packaging made of PET material, that can be easily recycled anywhere in the world. Most of SMIC’s products have recyclable protective material.

Use of Plant-Derived Plastic for Cushioning

By changing the cushioning material for product transport from chemical products to foamed plastic using plant-derived material, we are contributing to the prevention of global warming.

In addition, the use of wrapping material packed in a polythene bag instead of bulk packaging allows for reduction of the quantity used or ease of disposal.

As plant-derived plastic has excellent biodegradability and does not produce harmful gases such as dioxin during incineration, it also contributes to mitigating environmental pollution arising from disposal or incineration, and economizing fossil resources (resource saving).