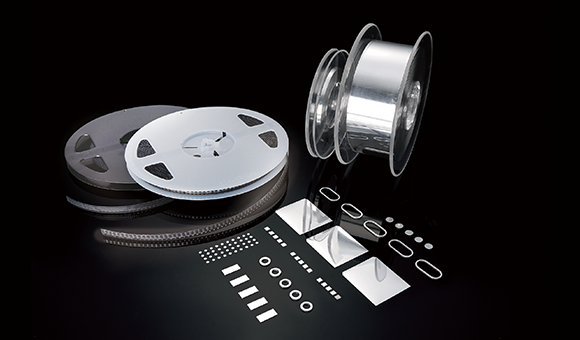

Solder alloys processed into various structures and shapes

These products are manufactured by processing solder alloys into various geometries and structures. Optimal soldering is achieved by selecting the appropriate alloy composition, dimensions, and one of five distinct preformed shapes.

*We can process various shapes and dimensions to meet customer requirements.

*We can process various shapes and dimensions to meet customer requirements.