Standard model with enhanced basic functions

- Saves more energy with cross nozzle and double heat insulation structure

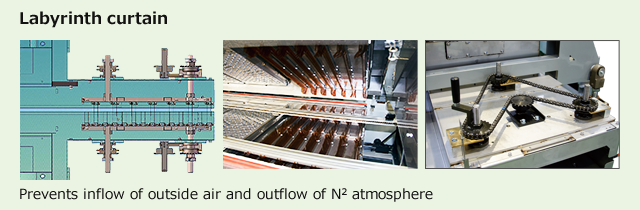

- Labyrinth curtain reduces N2 consumption

- Flux collection system enhances productivity

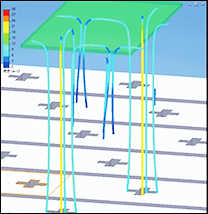

Heating capacity improved by the cross-nozzles

- Improves rectilinear propagation of hot air

- Stability and energy-saving effect at the motor low rotation

Low power consumption

- Power optimization through ECO-mode control developed by SMIC

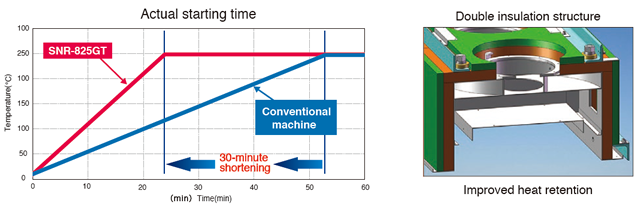

- Significant increased heat retention by the double insulation structure

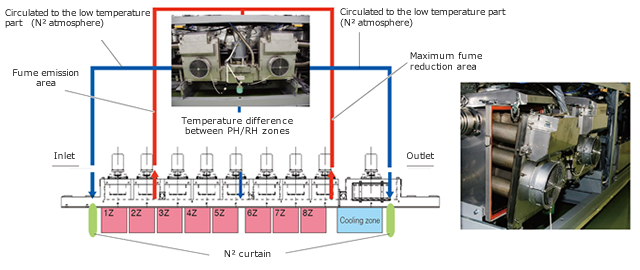

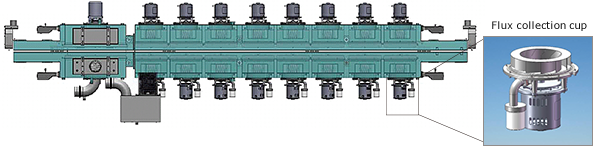

Flux Management System

- Uniquely developed the flux management system

- Tool-free easy maintenance

- Significantly higher flux collection efficiency by dual flux collection unit

- Reuse a paste abandoned container for flux collection

- Equipped with the flux management system in all zones as standard feature

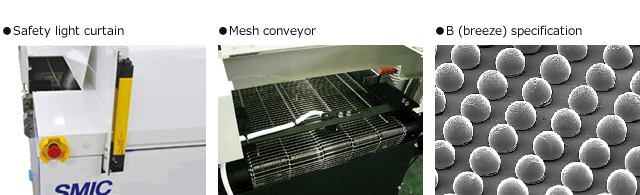

Low N2 consumption

- Top-bottom labyrinth curtain at inlet/outlet

- N2 curtain

- N2 reduction by injecting optimized amount

- Total consumption reduction by intelligent stand-by mode

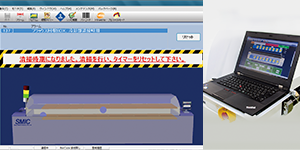

Notebook PC display panel

3D display for easy operation

Intelligent stand-by mode

Time reduction mode that achieves significant energy saving

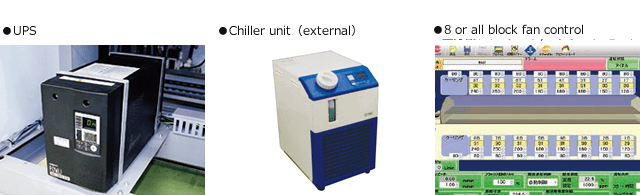

Other equipment

- PLC + PC control

- Heated zone flux management system

- PCB fall detection

- PCB counter

- ECO-mode operation (divided into 8 blocks)

- Oxygen analyzer

- Automatic oxygen concentration control

- Intelligent stand-by mode

- Profile measurement mode

- Independent fan control (tripartition)

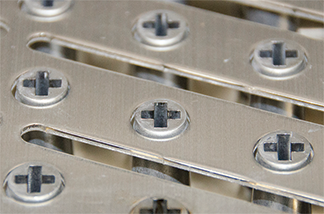

- Conveyor special surface treatment(chain, key materials and sprockets)

| SNR-725GT | SNR-840GT | ||

|---|---|---|---|

| Dimensions (L×W×H) | 3,000 x 1,326 x 1,430 mm | 5,300 x 1,390 x 1,460 mm | |

| Conveyor height | 900±20 mm | 900±20 mm | |

| Conveyor speed | 0.3 - 2.0 m/min | 0.3 - 2.0 m/min | |

| PCB dimensions | W: 50 - 250, L: 100 - 300, T: 0.8 - 3.0 mm | W: 50 - 400, L: 100 - 300, T: 0.8 - 3.0 mm | |

| Component height | ≦10mm [OP: 35mm], ≧5mm [OP: 25mm] | ≦10mm [OP: 35mm], ≧5mm [OP: 25mm] | |

| Heated zones | 7 | 8 | |

| Cooling zones | 1 | 1 | |

| Side edge clearance (select one) | 3 or 4 or 5 mm | 3 or 4 or 5 mm | |

| N2 (Nitrogen) gas supply | ≧99.999%, ≧0.4MPaG, max. 250NL/min | ≧99.999%, ≧0.4MPaG, max. 600NL/min | |

| N2 (Nitrogen) gas usage | Component height/STD:≦10mm, ≧5mm | 200NL/min | 300NL/min |

| Power requirement | 200V, max. 30kW, 90A, 3-phase | 200V, max. 30kW, 90A, 3-phase | |

| SNR-850GT | SNR-1050GT | ||

|---|---|---|---|

| Dimensions (L×W×H) | 5,700 x 1,490 x 1,460 mm | 6,500 x 1,490 x 1,460 mm | |

| Conveyor height | 900±20 mm | 900±20 mm | |

| Conveyor speed | 0.3 - 2.0 m/min | 0.3 - 2.0 m/min | |

| PCB dimensions | W: 50 - 500, L: 100 - 500, T: 0.8 - 3.0 mm | W: 50 - 500, L: 100 - 500, T: 0.8 - 3.0 mm | |

| Component height | ≦10mm [OP: 35mm], ≧5mm [OP: 25mm] | ≦10mm [OP: 35mm], ≧5mm [OP: 25mm] | |

| Heated zones | 8 | 10 | |

| Cooling zones | 1 | 2 | |

| Side edge clearance (select one) | 3 or 4 or 5 mm | 3 or 4 or 5 mm | |

| N2 (Nitrogen) gas supply | ≧99.999%, ≧0.4MPaG, max. 600NL/min | ≧99.999%, ≧0.4MPaG, max. 600NL/min | |

| N2 (Nitrogen) gas usage | Component height/STD:≦10mm, ≧5mm | 350NL/min | 350NL/min |

| Power requirement | 200V, max. 48kW, 140A, 3-phase | 200V, max. 48kW, 140A, 3-phase | |

| SNR-1451GT-B | SNR-1465GT | ||

|---|---|---|---|

| Dimensions (L×W×H) | 7,550 x 1,560 x 1,445 mm | 7,900 x 1,740 x 1,460 mm | |

| Conveyor height | 900±20 mm | 900±20 mm | |

| Conveyor speed | 0.3 - 2.0 m/min | 0.3 - 2.0 m/min | |

| PCB dimensions | W: 50 - 510, L: 100 - 510, T: 0.8 - 3.0 mm | W: 50 - 650, L: 100 - 700, T: 0.8 - 3.0 mm | |

| Component height | ≦10mm [OP: 35mm], ≧5mm [OP: 25mm] | ≦10mm [OP: 30mm], ≧5mm [OP: 25mm] | |

| Heated zones | 14 | 14 | |

| Cooling zones | 4 | 2 | |

| Side edge clearance (select one) | 3 or 4 or 5 mm | 3 or 4 or 5 mm | |

| N2 (Nitrogen) gas supply | ≧99.999%, ≧0.4MPaG, max. 600NL/min | ≧99.999%, ≧0.4MPaG, max. 600NL/min | |

| N2 (Nitrogen) gas usage | Component height/STD:≦10mm, ≧5mm | 400NL/min | 400NL/min |

| Power requirement | 200V, max. 63kW. 200A. 3-phase | 200V, max. 48kW, 200A, 3-phase | |

KIC system collaboration

Reduction of time to create atemperature profile

Automatic changeover by bar code

Functions that enable changeover without errors

Other optional equipment

- Up/down mechanism of top-bottom labyrinth curtains

- Automatic conveyor width adjustment (conveyor rail)

- Automatic conveyor width adjustment (warp prevention)