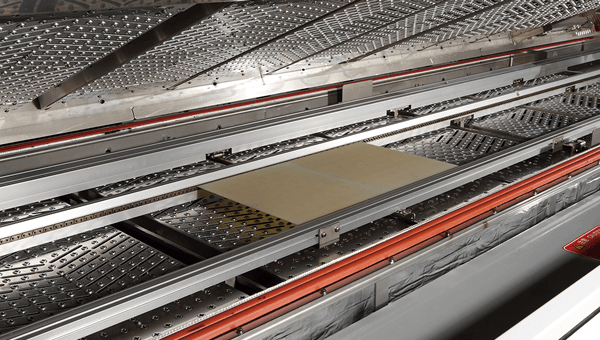

Dual lanes provide twice the production output

Compatible with a large size PCB in single mode

- Dual lanes provide twice the production output

- Compatible with a large size PCB in single mode

- Compatible with PCB of different sizes by adjusting the conveyor width and speed

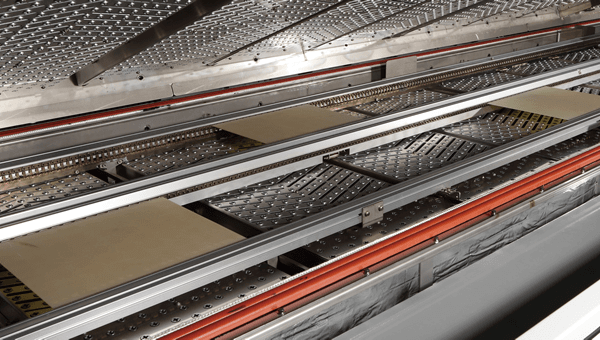

SNR-GT-D Dual lane image

Notebook PC display panel

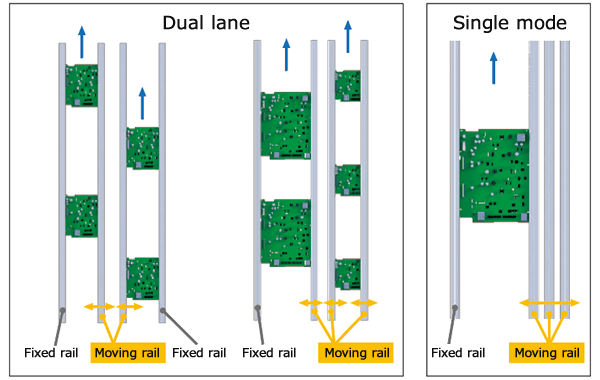

3D display for easy operation

Intelligent stand-by mode

Time reduction mode that achieves significant energy saving

ECO-mode function

Optimum setting according to work

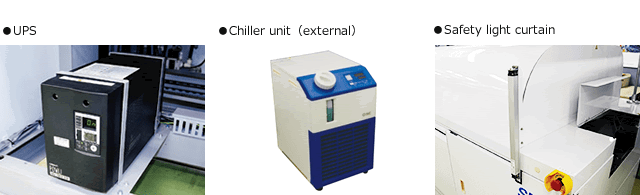

Other equipment

- PLC + PC control

- Heated zone flux management system

- PCB fall detection

- PCB counter

- Oxygen analyzer

- Oxygen analyzer

- Independent fan control (tripartition)

- Profile measurement mode

- Weekly timer

- Conveyor special surface treatment(chain, key materials and sprockets)

- Signal tower

| SNR-720GT-D | SNR-830GT-D | ||

|---|---|---|---|

| Dimensions (L×W×H) | 3,610 x 1,550 x 1,430 mm | 5,600 × 1,790 × 1,460 mm | |

| Conveyor height | 900±20 mm | 900±20 mm | |

| Conveyor speed | 0.3 - 2.0 m/min | 0.3 - 2.0 m/min | |

| PCB dimensions | Dual | W:50 - 200, L: 100 - 400, T: 0.8 - 3.0 mm x 2 lanes | W:50 - 300, L: 100 - 400, T: 0.8 - 3.0 mm x 2 lanes |

| Single | W: 200.1 - 350, L: 100 - 400, T: 0.8 - 3.0 mm x 1 lane | W: 300.1 - 590, L: 100 - 400, T: 0.8 - 3.0 mm x 1 lane | |

| Component height | ≦10mm [OP: 35mm], ≧5mm [OP: 25mm] | ≦10mm [OP: 30mm], ≧5mm [OP: 25mm] | |

| Heated zones | 7 | 8 | |

| Cooling zones | 1 | 1 | |

| Side edge clearance(select one) | 3 or 4 or 5 mm | 3 or 4 or 5 mm | |

| N2(Nitrogen) gas supply | ≧99.999%, ≧0.4MPaG, max. 600NL/min | ≧99.999%, ≧0.4MPaG, max. 600NL/min | |

| N2 (Nitrogen) gas usage | Component height/STD:≦10mm, ≧5mm | 300NL/min | 500NL/min |

| Power requirement | 200V, max. 30kW, 90 A, 3-phase | 200V, max. 48kW, 140A, 3-phase | |

| SNR-1030GT-D | |||

| Dimensions (L×W×H) | 6,300 x 1,790 x 1,460 mm | ||

| Conveyor height | 900±20 mm | ||

| Conveyor speed | 0.3 - 2.0 m/min | ||

| PCB dimensions | Dual | W:50 - 300, L: 100 - 700, T:0.8 - 3.0 mm x 2 lanes | |

| Single | W:300.1 - 590, L: 100 - 700, T: 0.8 - 3.0 mm x 1 lane | ||

| Component height | ≦10mm [OP: 30mm], ≧5mm [OP: 25mm] | ||

| Heated zones | 10 | ||

| Cooling zones | 2 | ||

| Side edge clearance(select one) | 3 or 4 or 5 mm | ||

| N2(Nitrogen) gas supply | ≧99.999%, ≧0.4MPaG, max. 600NL/min | ||

| N2 (Nitrogen) gas usage | Component height/STD:≦10mm, ≧5mm | 500NL/min | |

| Power requirement | 200V, max. 48kW, 140A, 3-phase | ||

KIC system collaboration[optional]

Reduction of time to create atemperature profile

Automatic changeover by bar code [optional]

Functions that enable changeover without errors

Other equipment

- Up/down mechanism of top-bottom labyrinth curtains

- Automatic conveyor width adjustment (conveyor rail)

- Automatic conveyor width adjustment (warp prevention)

- Display in English, or Chinese