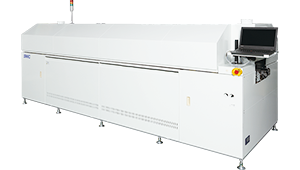

Air reflow oven that utilizes know-how of many years

- High versatility and easy maintenance

- Can also be used as an adhesive metallization oven

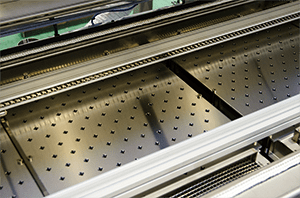

Cutting-edge cross-nozzle heater

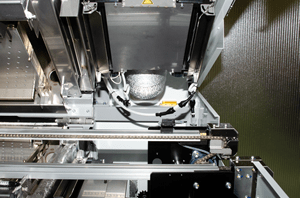

Cooling cross-flow fan

(with air volume adjustment mechanism)

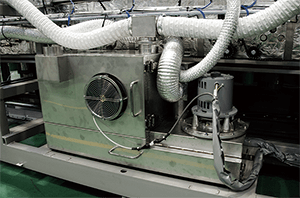

Flux collection system

- Notebook PC

- 3 block control

- Cooling cross flow fan

- Heated zone flux management system

- Adjustment of top/bottom cooling air volume

- PCB fall sensor

- Temperature profile measurement mode

- Maintenance timer

- Signal tower

- Specific conveyor height

- Display in Japanese, English, or Chinese

- Specific color

- Heating zone ECO-mode (divided into 8/16 blocks)

- Opens/closes the intermediate stop position of the oven

- Automatic conveyor width adjustment

- Nitride coating on conveyor

(chain/key materials, sprockets) - PCB warp prevention mechamism

- Automatic width adjustment for warp prevention mechanism

- In-out feeder free rollers

- Operator mode function

- Signal line connector (SMEMA standard)

- UPS power supply

- Safety light curtain

(confirm opening / closing of the rid) (oven closed status sensor check) - Automatic chnageover by barcode reader

| SAR-825GT | |

|---|---|

| Dimensions (L×W×H) | 3,800 x 1,330 x 1,460 mm |

| Conveyor height | 900±20 mm |

| conveyor speed | 0.3 - 2.0 m/min |

| Board dimensions | W: 50 - 250, L:100 - 400, T: 0.8 - 3.0 mm |

| Component height | ≦35 mm, ≧25 mm |

| Heated zones | 8 |

| Cooling zones (Cross flow fan system) | Top side 2, bottom side 1 |

| Side edge clearance (select on) | 3 or 4 or 5 mm |

| Power supply | 200V, max. 30kW, 90A, 3-phase |