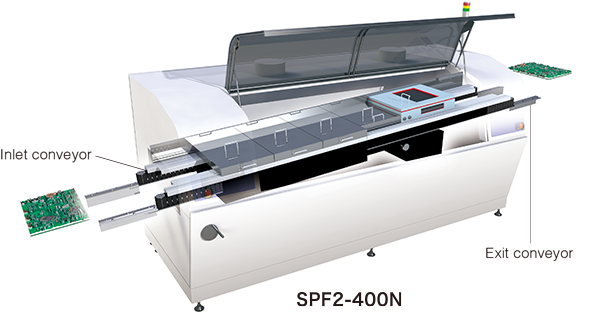

Energy-saving automatic stable pressure flow type soldering system

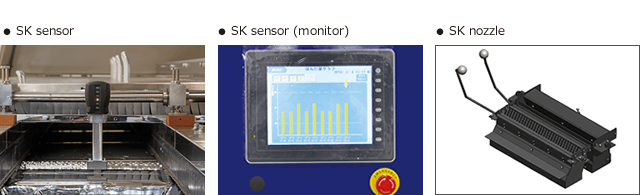

- Adoption of NH deflect plate makes stable pressure and mirror surface-like solder flow

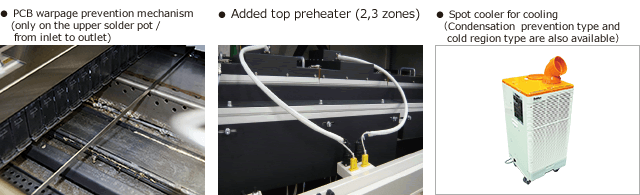

- Enhanced through-hole fillings by strengthened preheaters and stronger wave pressure

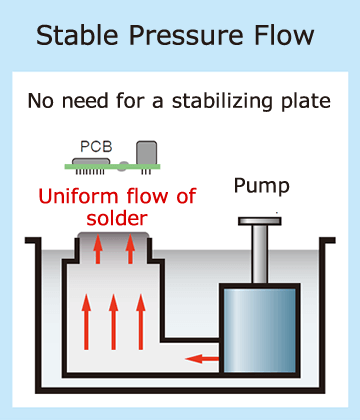

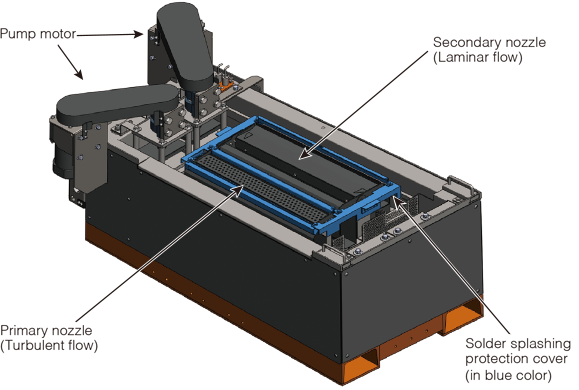

Stable Pressure Flow

- Eliminates the need for a stabilizing plate

- Allows easy pot cleaning without disassembly

- Stable flow wave

- Without a stabilizing plate, no clogging of oxide occurs and offering stable solder flow

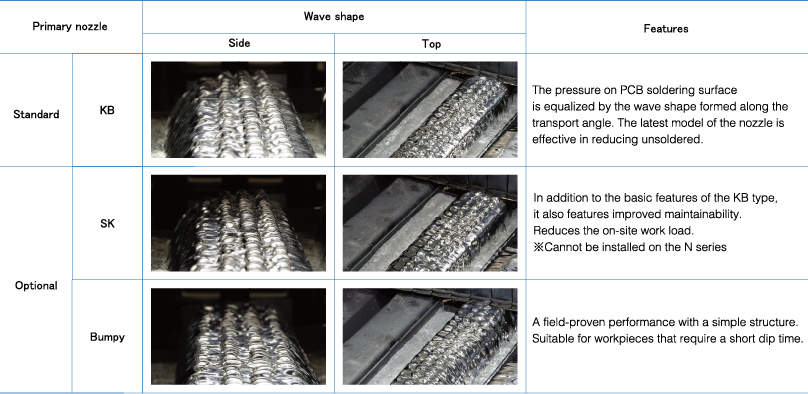

A primary nozzle suitable for the workpiece can be selected

- Stable flow wave is compatible with a flow wave height of over 10 mm

- Full chamber system

- Equipped with a flux management system as standard

- Ensures high quality of the product

- Reduces oxide of solder

- Easy-maintenance structure

- Solder splashing protection cover as a standard feature

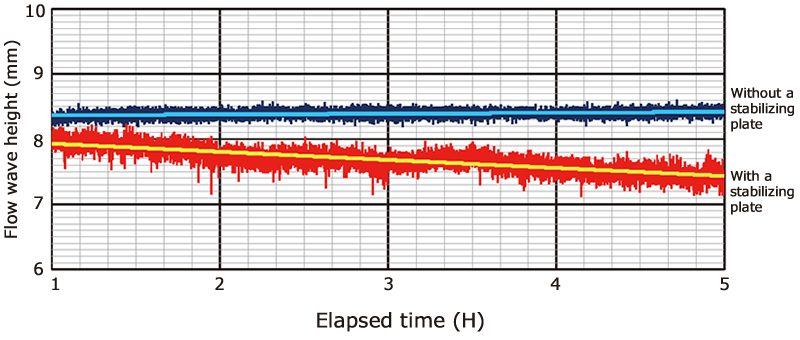

Stable higher wave realized by the NH deflecting plate

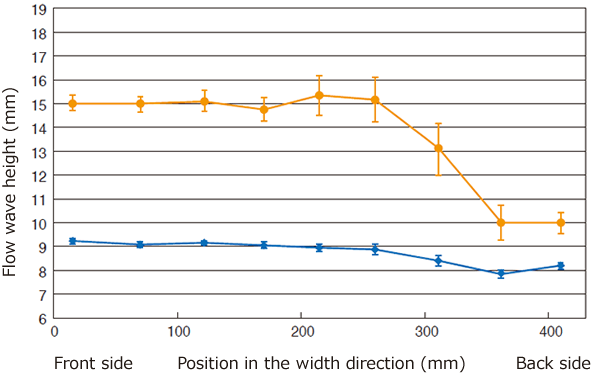

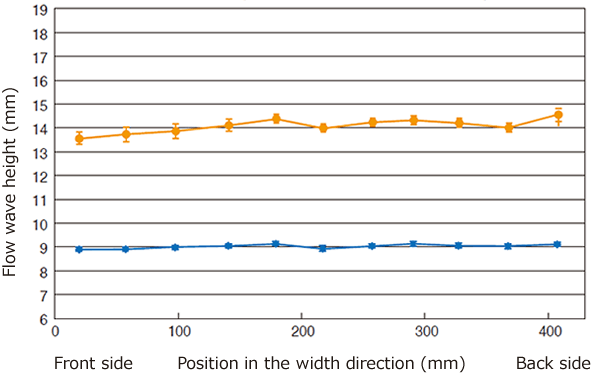

Comparison of wave conditions

With a conventional deflecting plate

With a NH deflecting plate

Flow wave height

with a conventional deflecting plate

Flow wave height

with a NH deflecting plate

N-Series for N² ambient wave soldering

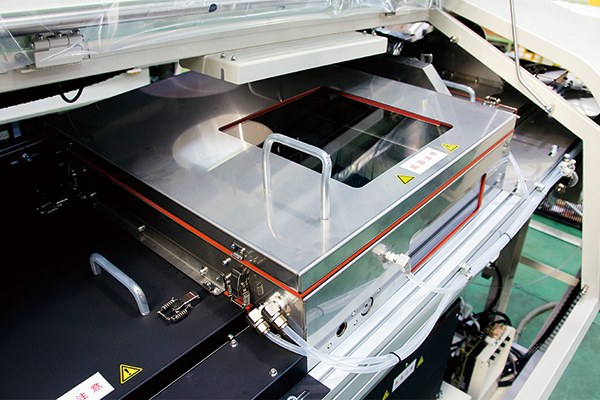

Stable pressure Solder pot

- Touch panel + PLC control

- Preheaters: IR panel heater × 4

- Conveyor height 780 ±20 mm

- Conveyor resin fingers

- External flow volume

- Width adjustment indicator

- PCB bottom surface cooling fan unit

- Signal tower

- Loading/unloading chain conveyor with flanges

- Oxygen analyzer (N-Series)

- Automatic solder pot in/out and up/down mechanism (N-Series)

- Solder splash protection cover (N-Series)

- Full nitride coating

- Nail cleaning unit

- Conveyor elevating mechanism

- Solder pot connector specifications

- Pulsating jet flow

- Wave-height side guide

- Caster

- Soldering pot automatic up & down (N Series: standard)

- Soldering pot automatic in & out(N Series: standard)

| SPF2-300 | SPF2-300N | ||

|---|---|---|---|

| Dimensions (L×W×H) | 4,340 x 1,340 x 1,540 mm | 4,340 x 1,340 x 1,540 mm | |

| Conveyor height | 780 ±20mm | 780 ±20mm | |

| Conveyor speed | 0.5 - 2.0 m/min | 0.5 - 2.0 m/min | |

| PCB dimensions (W×L) | 50 x 100 - 300 x 450 mm | 50 x 100 - 300 x 450 mm | |

| Component height (highest) | ≦100mm, ≧5mm | ≦50mm, ≧5mm | |

| Preheater (heated zone length) | 1,600 (400/zone x 4) mm | 1,600 (400/zone x 4) mm | |

| Solder pot capacity (approx.) | 360kg (M705, Sn - 3.0Ag - 0.5Cu) | 360kg (M705, Sn - 3.0Ag - 0.5Cu) | |

| N2 (Nitrogen) gas supply | - | ≧99.999%, ≧0.3MPaG, max. 700NL/min | |

| N2 (Nitrogen) gas usage | Component height/STD:≦100mm, ≧5mm *Exit side labyrinth height:Same as PCB transfer |

- | 300NL/min |

| Air supply | - | ≧0.5MPaG | |

| Power requirement | 200V, approx. 32.5kW, 100A, 3-phase | 200V, approx. 32.9kW, 100A, 3-phase | |

| SPF2-400 | SPF2-400N | ||

|---|---|---|---|

| Dimensions (L×W×H) | 4,340 x 1,340 x 1,540 mm | 4,340 x 1,340 x 1,540 mm | |

| Conveyor height | 780 ±20mm | 780 ±20mm | |

| Conveyor speed | 0.5 - 2.0 m/min | 0.5 - 2.0 m/min | |

| PCB dimensions (W×L) | 50 x 100 - 400 x 450 mm | 50 x 100 - 400 x 450 mm | |

| Component height (highest) | ≦100mm, ≧5mm | ≦50mm, ≧5mm | |

| Preheater (heated zone length) | 1,600 (400/zone x 4) mm | 1,600 (400/zone x 4) mm | |

| Solder pot capacity (approx.) | 360kg (M705, Sn - 3.0Ag - 0.5Cu) | 360kg (M705, Sn - 3.0Ag - 0.5Cu) | |

| N2 (Nitrogen) gas supply | - | ≧99.999%, ≧0.3MPaG, max. 700NL/min | |

| N2 (Nitrogen) gas usage | Component height/STD:≦100mm, ≧5mm *Exit side labyrinth height:Same as PCB transfer |

- | 300NL/min |

| Air supply | - | ≧0.5MPaG | |

| Power requirement | 200V, approx. 32.5kW, 100A, 3-phase | 200V, approx. 32.9kW, 100A, 3-phase | |

| SPF2-500 | SPF2-500N | ||

|---|---|---|---|

| Dimensions (L×W×H) | 4,640 x 1,440 x 1,540 mm | 4,640 x 1,440 x 1,540 mm | |

| Conveyor height | 780 ±20mm | 780 ±20mm | |

| Conveyor speed | 0.5 - 2.0 m/min | 0.5 - 2.0 m/min | |

| PCB dimensions (W×L) | 50 x 100 - 500 x 600 mm | 50 x 100 - 500 x 600 mm | |

| Component height (highest) | ≦100mm, ≧5mm | ≦50mm, ≧5mm | |

| Preheater (heated zone length) | 1,600 (400/zone x 4) mm | 1,600 (400/zone x 4) mm | |

| Solder pot capacity (approx.) | 520kg (M705, Sn - 3.0Ag - 0.5Cu) | 520kg (M705, Sn - 3.0Ag - 0.5Cu) | |

| N2 (Nitrogen) gas supply | - | ≧99.999%, ≧0.3MPaG, max. 700NL/min | |

| N2 (Nitrogen) gas usage | Component height/STD:≦100mm, ≧5mm *Exit side labyrinth height:Same as PCB transfer |

- | 450NL/min |

| Air supply | - | ≧0.5MPaG | |

| Power requirement | 200V, approx. 32.5kW, 100A, 3-phase | 200V, approx. 32.9kW, 100A, 3-phase | |