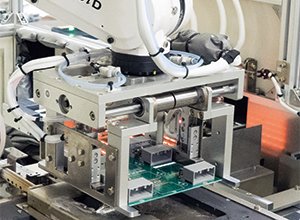

Automatic selective dip-soldering machine best suited for high-mix low-volume production

The robot conveys the PCB to the nozzle

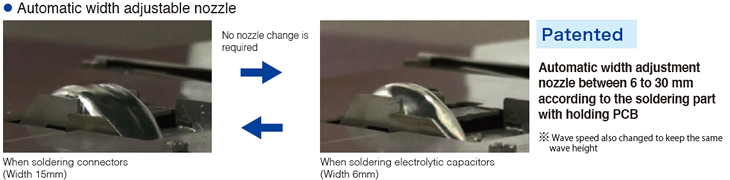

- The newly developed automatic width adjustable nozzle makes it possible that just one nozzle accepts different items

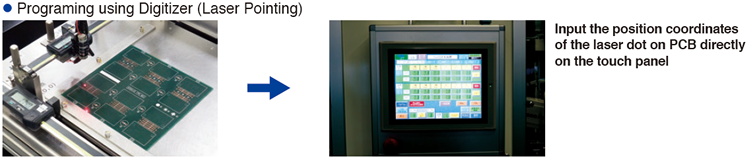

- The newly developed programing using digitizer (laser pointing) for easy operations

- 6-axis robot achieves reduction in size and price

- Incorporation into production lines is possible with in-line system

- Automatic width adjust of PCB conveyor rail and holders

- Flux Flowmeter (leak detection)

- Upper pre-heater unit (3 halogen lamps)

- PCB size for out of specification (please consult)

| SNF-2017ST | |

|---|---|

| Dimensions (L×W×H) | 2,150 x 1,300 x 1,500 mm |

| Weight (Approx.) | 1,500 kg |

| Utility | 3-Phase 200 V ± 10% 19 kVA AIR;40 l/min φ10 joint N2;10 l/min φ10 joint |

| Board dimensions | W: 100 - 250, L: 100 - 200, T: max. 40 mm (from PCB topside), PCB edge dead space: 3 mm or more |

| Transfer system | PCB traveling by 6-axis robot with chuck (operable by touch panel) |

| Fluxer unit | Pressurized Spraying Nozzle (XY Drive),Upward/downward-moving mist collection duct |

| Preheating | Halogen lump (1.2 kw × 6),Heat-resistant glass |

| Soldering | Point soldering nozzles for variable width, Solder Pot: 100 kg, Servo motor system for soldering pump,/ Corrosion-proof surface treatment using Hot N2 |

| Cooling unit | Cooling fan with air |

*Products in MPF series can be customized upon request of the customer; please contact our sales representative