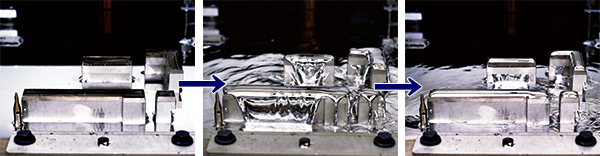

Static pressure type selective soldering offers energy-saving and high quality

- Customized static pressure wave method enhances through-hole fillings

- Use of pitch-feed mechanism enables mass production

- Customized nozzle design available according to board size and/or shape

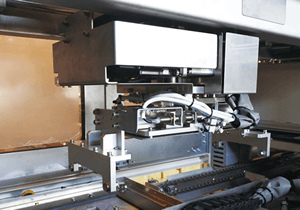

4-axis robot (MPF-2077ST)

- Touch panel + PLC control

- Signal tower

- Weekly timer

- Preheater (convection/halogen lamps)

- Fluxer: XY-axis servo control

- Pressurized flux tank

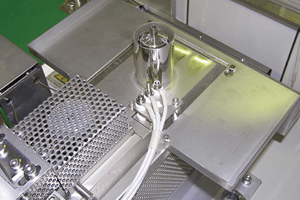

Point nozzle (MPF-2077ST)

- Top preheater (convection/halogen lamps)

- Cooling fan unit

- Solder inclination cutting mechanism

- Wave height control mechanism

- Solder dross prevention N₂ cover system

- Return conveyor

- Point nozzle

| MPF-2077ST (round type) | |

|---|---|

| Dimensions (L×W×H) | 2,800 x 1,460 x 1,650 mm |

| Utility | 3-phase, AC 200V, 44kVA, Air: φ10joint |

| PCB dimensions* (solderable range W×L) |

W: 80 - 250, L: 80 - 330, T: max. 50mm (230 x 310 mm [From the board center]) |

| Transfer system | Conveyor pallet rotation system |

| Fluxer unit | XY axis programmable |

| Preheater unit | Halogen heater (1.2kW × 7) |

| N² (Nitrogen) gas supply** | 5NL/min [Flow shaft part] |

| Cooling unit | Cooling fan with air |

* H: Under the board

** OP: Optional N₂ cover is required separately.

| MPF-2003ST (in-line type) | |

|---|---|

| Dimensions (L×W×H) | 3,070 x 1,206 x 1,650 mm |

| Utility | 3-phase, AC 200V, 19kVA, Air: φ10joint |

| PCB dimensions* (solderable range W×L) |

W: 80 - 250, L: 80 - 330, T: max. 50mm (230 x 310 mm [From the board center]) |

| Transfer system | PCB direct transfer |

| Fluxer unit | XY axis programmable |

| Preheater unit | 6kW [OP:Halogen heater] |

| N² (Nitrogen) gas supply** | 5NL/min [Flow shaft part] |

| Cooling unit | Cooling fan with air |

* H: Under the board

** OP: Optional N₂ cover is required separately.