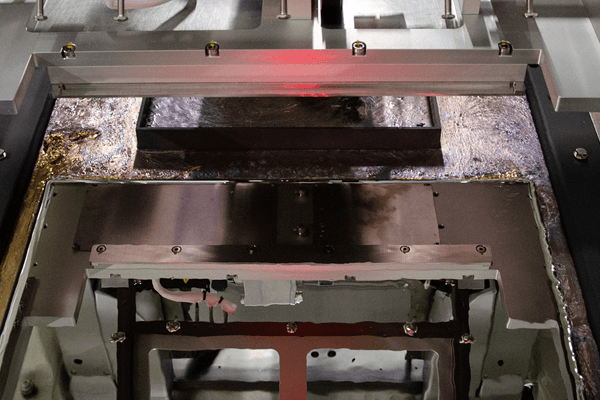

Soldering quality with unique internal heat circulation system will inprove

- Internal heat circulation system balances soaking and suppress dross generation

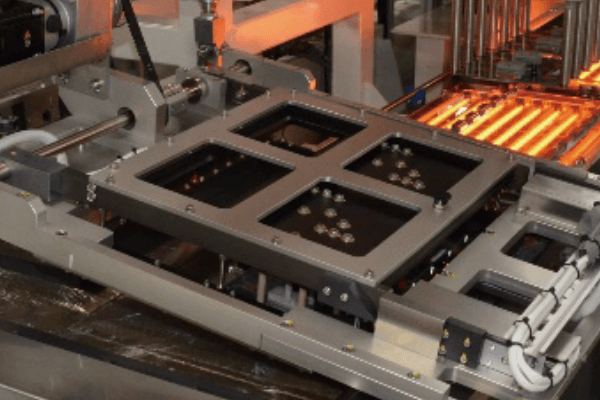

- Mask pallet preheating system achieves soaking of work

- Multi-angle control that enables various dip soldering

Internal heat circulation while keep the mirror surface

Utilize heat source of Solder pot for preheating mask pallet Efficient soaking of work

- Multi-angle control by 4-axis robot

Various dip soldering can be set

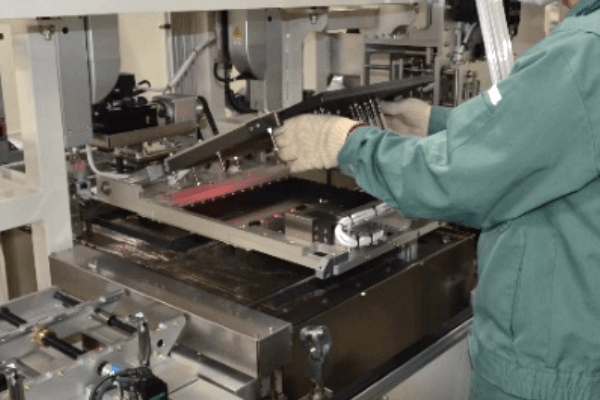

- Tool-free mask pallet changing mechanism

Switch models in a short time

- Operation touch panel

- Signal tower

- Haloge lamp-type preheater

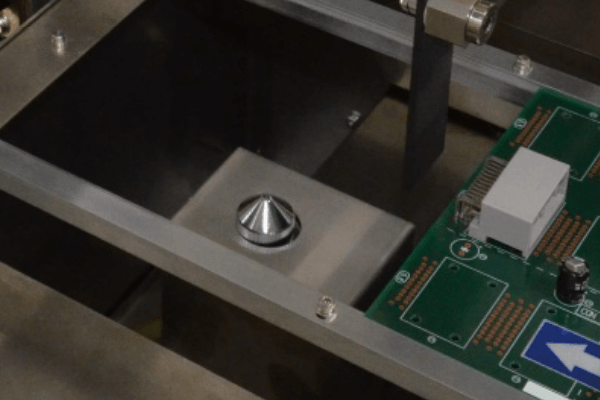

- Fluxer: XY axis servo motor operation programmable

- XY drive spray fluxer

Flux to target location can be applied

| LPD-2019M | |

|---|---|

| Dimensions (L×W×H) | 3,310 x 1,550 x 1,650 mm |

| Utility | 3-phase, AC 200V, 26kVA, AIR: φ10joint |

| PCB dimensions | W: 150 - 250, L: 150 - 330, T: max.50mm (Frome PCB topside), Bottom clearance:max. 10mm |

| Transfer system | PCB traveling by robot with chuck |

| Fluxer unit | Pressurized spraying nozzle (XY Drive) |

| Preheater unit | Halogen lump(1.0kWx23/1st:Upper5,Bottom9/2st:Bottom9), Heat-resistant glass |

| Soldering | Internal heat circulation, Solder pot:500kg, Motor system for soldering pump, Corrosion-proof surface treatment |

| Cooling unit | Cooling fan with air |